LBO

Lithium triborate (LiB3O5 or LBO) has the following exceptional properties that make it a very important nonlinear crystal:

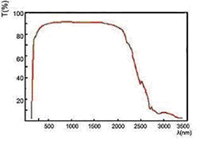

- broad transparency range from 160nm to 2600nm;

- high optical homogeneity (δn≈10-6/cm) and being free of inclusion;

- relatively large effective SHG coefficient (about three times of KDP);

- high damage threshold (18.9 GW/cm2 for a 1.3ns laser at 1053nm);

- wide acceptance angle and small walk-off;

- type I and type II NCPM in a wide wavelength range;

- Spectral NCPM near 1300nm.

|

|

LBO is grown with the flux method. It is a negative biaxial crystal, with the principal axes X, Y, and Z (nz >ny>nx) parallel to the crystallographic axes a, c, and b, respectively.

Figure1. Transmission spectral of LBO

Structural and Physical Properties |

Crystal Structure |

Orthorhombic, Space group Pna21, Point group mm2 |

Cell Parameters |

|

Melting point |

About 834°C |

Optical homogeneity |

δn≈10-6/cm |

Mohs hardness |

6 |

Density |

2.47 g/cm3 |

Thermal expansion coefficients |

αx=10.8x10-5/K,αy= -8.8x10-5/K,αz=3.4x10-5/K |

Hygroscopic susceptibility |

Low |

Absorption coefficient |

<0.01%/cm at 1064nm |

Thermal conductivity |

3.5W/mK |

|

Optical Properties

LBO has the largest damage threshold of all the commonly-used inorganic NLO crystals. Therefore, it is the best candidate for high average power SHG and other nonlinear optical processes.

Damage Threshold at 1053nm

Crystal |

Energy Density (J/cm2) |

Power Density (GW/cm2) |

Ratio |

KTP

KDP

BBO

LBO |

6.0

10.9

12.9

24.6 |

4.6

8.4

9.9

18.9 |

1.00

1.83

2.15

4.10 |

LBO’s applications

- SHG and THG for middle and high power Nd: lasers at 1064nm for medical, ?industrial and military applications;

- SHG for Ti:Sapphire, Alexandrite and Cr:LiSAF lasers;

- SHG and THG of high power Nd: lasers at 1342nm &1319nm for red and blue laser

- SHG for the Nd: Lasers at 914nm & 946nm for blue laser.

- The VUV output at 187.7 nm is obtained by sum-frequency generation.

- NCPM SHG over a broad wavelength range from 900nm-1700nm was measured.

- Phase matching process cutoff: SHG-554 nm fundamental, THG-794 nm, SFM-down to 160 nm.

- Optical Parametric Amplifiers (OPA) and Oscillators (OPO) application;

SHG and THG at Room Temperature

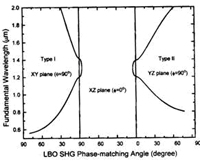

LBO is phase matched for the SHG and THG of Nd:YAG and Nd:YLF lasers, using either type I or type II interaction. For the SHG at room temperature, type I phase matching can be reached and has the maximum effective SHG coefficient in the principal XY and XZ planes in a wide wavelength range from 551nm to about 3000nm. LBO is the first choice for making doubler or tripler for lasers such as Nd:YAG where high power density, high stability, and long time operation are required.

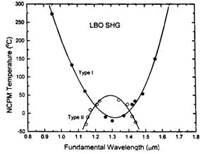

Figure 2.SHG of LBO at room temperature

Non-Critical Phase-Matching

Non-Critical Phase-Matching (NCPM) of LBO is featured by no walk-off, very wide acceptance angle and maximum effective coefficient. It promotes LBO to work in its optimal condition. As shown, type I and type II non-critical phase-matching can be reached along x-axis (θ=90°, φ=0°) and z-axis (θ=0°, φ=0°) at room temperature, respectively.

SHG conversion efficiencies of more than 70% for pulse and 30% for cw Nd:YAG lasers, and THG conversion efficiency over 60% for pulse

Nd:YAG laser have been observed. With good output stability and beam quality. |

Properties of type I NCPM SHG at 1064nm |

NCPM Temperature |

148°C |

Acceptance Angle |

52 mrad-cm1/2 |

Walk-off Angle |

0 |

Temperature Bandwidth |

4°C-cm |

Effective SHG Coefficient |

2.69×d36(KDP) |

Figure3. NCPM temperature tuning of LBO

LBO’s OPO and OPA

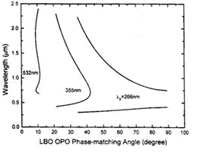

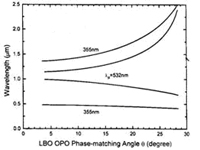

LBO is an excellent NLO crystal for OPO and OPA with a widely tunable wavelength range and high powers. The unique properties of type I and type II phase matching as well as the NCPM leave a big room in the research and applications of OPO and OPA.

Figure 4.Type I OPO tuning curves of LBO Figure 5. Type II OPO tuning curves of LBO

LBO Specifications

Transmitting wave-front distortion: less than λ/8 @ 633nm

Dimension tolerance: (W±0.1mm)×(H±0.1mm)×(L+0.2/-0.1mm)

Clear aperture: central 90% of the diameter

No visible scattering paths or centers: 20&130mW green laser

Flatness: λ/8 @ 633nm

Scratch/Dig code: 10/ 5 to MIL-O-13830A

Parallelism: better than 20 arc seconds

Perpendicularity: 5 arc minutes

Angle tolerance: Δθ< ±0.25°, Δφ<±0.25°

Coating: Single-band, dual-band and broad-band AR-Coating on LBO surface are available.

Reflection Loss: R<0.2%@1064nm, R<0.5%@532nm, R<1.0%@355nm

Damage threshold [GW/cm2]:

>10 for 1064nm, TEM00, 10ns, 10HZ (polished only)

>1 for 1064nm, TEM00, 10ns, 10HZ (AR-coated)

>0.5 for 532nm, TEM00, 10ns, 10HZ (AR-coated)

Quality Warranty Period: one year under proper use.

Sino-crystal Warrant

- Strict quality control;

- High inside quality without any defection.

- Large crystal size up to 20x20x40mm3

- High damage AR-coating

- Large quantity standard products in-stock

- Fast delivery. (For crystal in stock, 3 days ARO; for polished only, 1-2 weeks ARO. For coated crystal: 3-4 weeks ARO)

NOTE

1. LBO has a very low susceptibility to moisture. Users are advised to provide dry conditions for both the use and preservation of LBO.

2. Polished surfaces of LBO require precautions to prevent any damage.

|